When we deal with metal chip removal, we can face various machining dimensions.

The most common processes are those related to minuscule parts, which concern small dimensions, for the most varied target sectors.

As the size of the working cube increases different and specific tools and technologies are needed according to needs of this kind of machining.

It is normal, if not obvious, that a company that manufactures small parts needs completely different Machine Tools compared to a company that processes raw parts on LARGER WORKING CUBES, of a certain size, which therefore require specific power and equipment.

In this case, I am not referring to material differences, but I would first like to focus your attention on the dimensions and the working cube.

Let’s see the following example to understand how the level of complexity increases in processes carried out on these working cubes …

VALVES MACHINING FOR OIL&GAS INDUSTRY

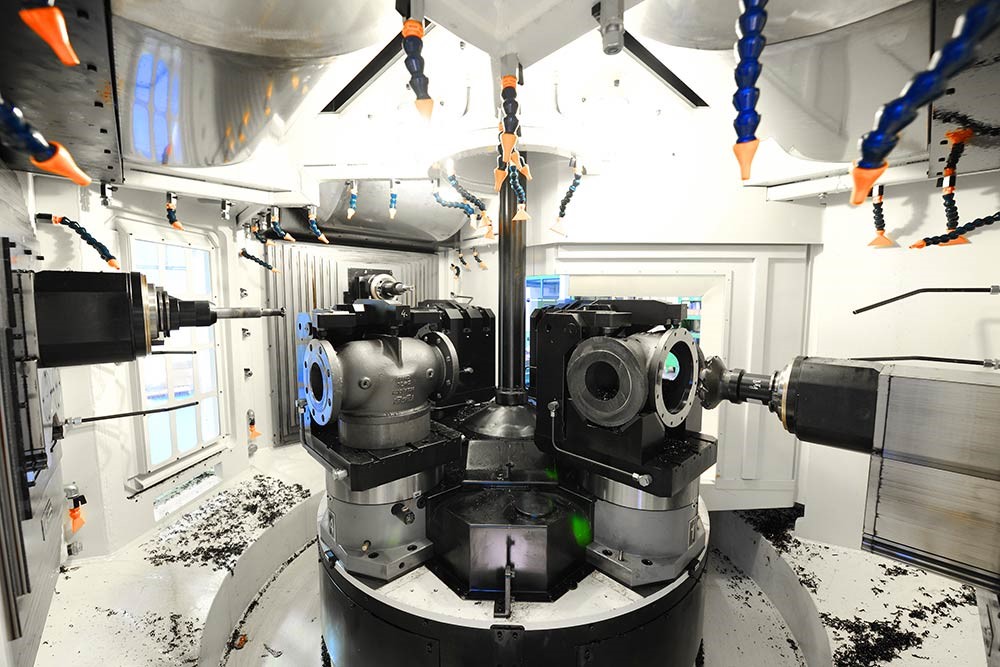

In this photograph you can see a very particular machining of cast iron, steel and stainless steel valves for the OIL&GAS industry.

The image shows a specific valve size, however, as you can guess, the processing includes a very wide and complete range of sizes.

Thanks to certain well-conceived equipment, multiple sizes of valves can be covered within that working cube, without replacing the equipment itself.

The only thing that changes are elements that include quick systems, without using keys and screws, in order to make the change from one size to another very fast, even less than 15 minutes.

This kind of Machine Tool performs 100% of machining operations, including drilling, milling, threading and, in some cases (with a special option), it is also possible to perform turning with a lathe head.

Now you can understand how many variations can be made on a 500mm working cube so as to obtain exceptional results, without changing equipment.

Or even, as in this case, without going from one Machining Center to another to complete the manufacturing.

THE MISTAKE YOU SHOULD ABSOLUTELY AVOID

At this point in your reading, you may be wondering which are the correct tool and technology to be able to machine components of important dimensions on a 500mm working cube (including equipment), as best you can.

Certainly the answer depends on a series of evaluations and characteristics related to YOUR specific case.

Your situation is different from that of another company because business management and objectives change from case to case.

But the starting point, according to my experience, is definitely to identify NEW and INNOVATIVE solutions, which allow you to achieve better results than those of your competitors.

NEW AND INNOVATIVE SOLUTIONS = BETTER RESULTS

To do this, you have to search for different solutions, which are as far apart as possible from the usual (and taken for granted by now) choices of your competitors.

Follow me because this point is important.

If you know me and read my contents, you have probably heard me talking about the importance of being different from your competitors in order to cover new market segments that allow your company to earn more.

This reasoning sounds simple and logical, doesn’t it?

Yet, it is not.

Most of the users of Machine Tools carry on looking for usual solutions, COPYING hand in hand what their competitors do.

However this approach is a losing proposition, because it does not allow you to achieve different results. The only result will be to throw your company into the price war and to be in a “conformed” market.

How do you expect to achieve extraordinary results if you continue to make completely “ordinary” choices?

EXTRAORDINARY RESULTS NEED BRAVE AND EXTRAORDINARY CHOICES

Not by chance, “EXTRAordinary” is a word that differs from “ordinary”, since it is something that requires an UNUSUAL attitude, namely out of the ordinary.

So, as mentioned, you have to stand out.

And to do so today you have a unique opportunity…

THE CORRECT TOOL FOR MACHINING METAL COMPONENTS ON A 500mm CUBE

As mentioned, the ability to stand out from the crowd, from all those companies that, for fear or lack of initiative, always choose the same technologies and types of Machine Tools, certainly plays an important role.

A problem that is too often overlooked, which does not allow you to evaluate truly efficient alternatives that are able to bring significant benefits and results to your production department.

Which alternative to choose instead of the ordinary Machining Centers?

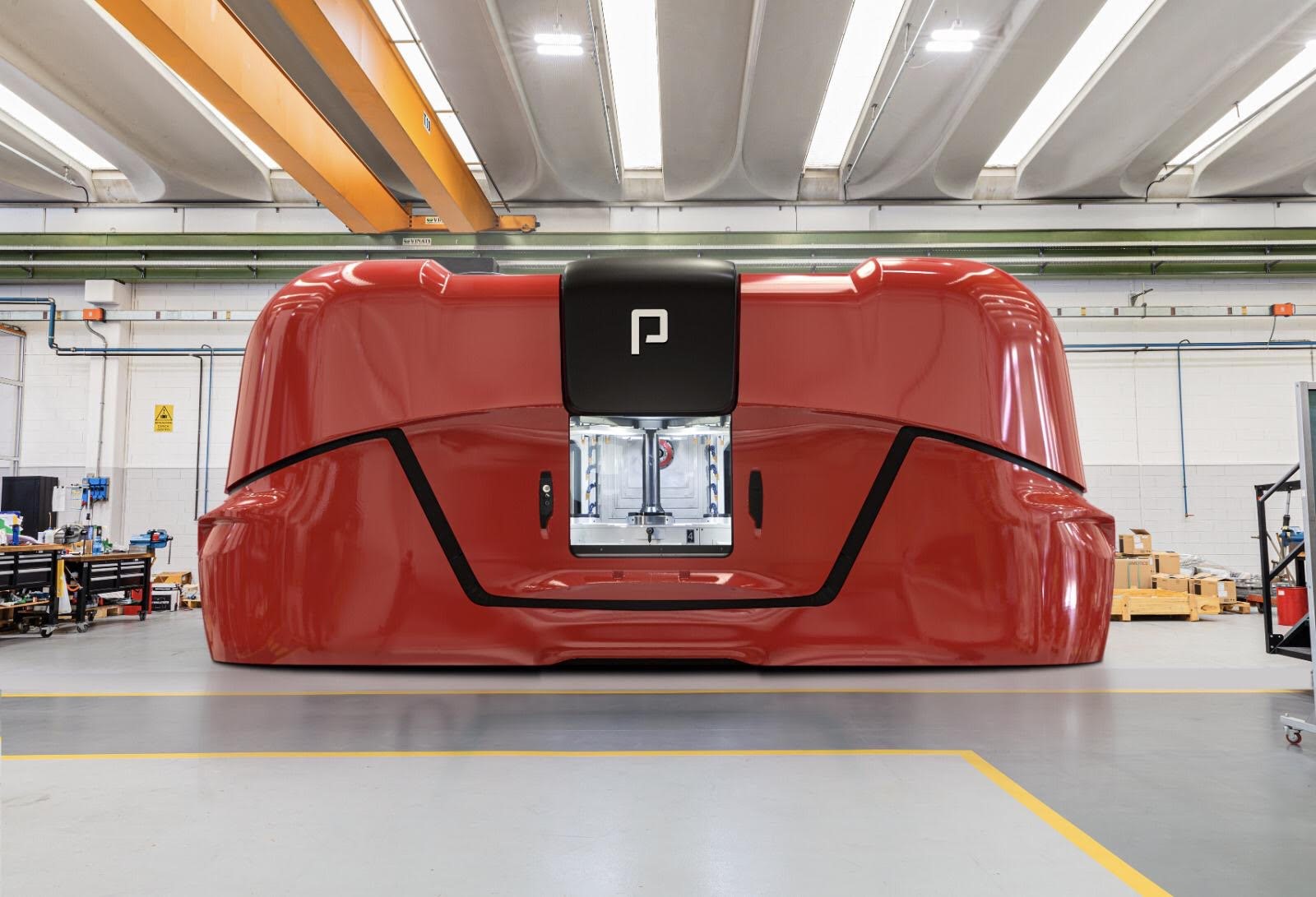

The best and most innovative alternative on the market for 500mm working cubes is, without terms of comparison, the one proposed by PORTASOLUTIONS.

In fact, PORTASOLUTIONS has just launched the new PORTACENTER ISO50/HSK100, 3-spindle model, which allows users to perform exceptional metalworking on a 500mm working cube.

We are talking about a completely new and revolutionary technology, based on the 3-spindle philosophy, which allows to lower the cycle time by 3 times compared to 1 single Machining Center and to increase the levels of precision in production, obtaining exceptional CPK values.

A numerical control Machine Tool with turning work module option, with tool changeover with 24 or 40 places, only for lathe operations.

This machine replaces battery machining centers and lathes, making you more productive and competitive.

Here are some features of this new model:

- 4 stations and 3 modules

- closed cell base for maximum stiffness

- 3 strong XYZ modules, horizontal and made from die cast iron with a ISO50 or HSK100 tool coupling

- Each ATC equipped with 40 tool pockets, 120 total tools in the machine

- 4 satellite tables in continuous mode (360,000 positions)

- 2 or 4 through pallet oil supplies for each satellite table

- Standard ISO programming

- Siemens® or Fanuc® CNC

The importance of a technology is directly proportional to the production METHOD and management processes by which it is supported, as well as the ability of the company and the production manager to differentiate themselves from the competition.

Keep doing “as it has always been done” or enter into a new dimension and level of production?

Take your pick … but remember that many companies of your sector have already moved ahead without wasting any more time.

Postponing now could cost a lot tomorrow!

If you are a user of CNC Machine Tools for metalworking and you need to work components on a 500mm WORKING CUBE … NOW you have the opportunity to evaluate a new technology dedicated to you, supported by a Technical Tutor, an expert in the field who will guide you, step by step, searching for the best production model for your specific case.

ASK FOR A DIRECT CONSULTATION

with one of our Technical Tutors.

Send an email to porta@flexible-production.com to get more information.

If you want to go deeper on the topics of Flexible Production and Competitive Production

CLICK HERE

www.flexibleproductionbook.com

My book dedicated to users of Machine Tools who want to make the leap in quality, is waiting for you!!!

To your results,

Maurizio Porta

Master Trainer PORTA PRODUCTION METHOD

Ita

Ita Deu

Deu