Please note how the machining center has a massive presence in industry. In fact, it occupies square miles in production departments all over the world; in fact, it is one of the most common machines in the world.

Now, if EVERYONE has this technology available… let me guess: your competitor will also have one or more machining centers at its company.

When you run up against your competitors, whether you produce the same product in a good way or bad way, generally speaking you are dealing with the following aspects, in order to have some chance of taking home the job.

YOU AND YOUR COMPETITOR BEHAVE THE SAME WAY,

MORE OR LESS…

When purchasing one or more MACHINING CENTERS, your instinct tells you to FIGHT in order to obtain the best price, with hardline negotiations, pitting many competitors against each other and hoping to pay the less for your machines thanks to your negotiating skills.

Once the machine has been purchased, the focus shifts onto other elements, the most important of them being the cost of labour which, as everyone knows, in ‘developed countries’ bears significantly on the final cost of the product.

In this case too, the company tries to pay personnel the lowest wages possible compared to the competition.

Years ago, and today still, these analyses have spawned the various de-localisation ideas aimed at cutting this specific cost, the alternative is to automate with robot which, in any case, force you to eliminate a simple operator and have one specialized on the robot.

This is a good way if you succeed in utilizing the specialized one on many robotized systems, or if you already have in your company a specialized operator working on other machines.

Moving on to the next item, energy is another topic that is very dear to manufacturing companies, as it has a direct affect on cost.

In developed countries, the energy market is practically locked up, with very tight negotiation margins, for your company as well as your competitor’s.

Raw materials are the other variable, but if you think you are the only one making good purchasing choices whereas your competitor is not, well allow me to tell you that you are way off track.

Both of you try in every way to purchase at the best price through various volume discount contracts, or implementing a plan, and so on.

Your company’s general costs are strictly tied to how your company is organised.

On average, small businesses have lower company costs, while larger companies bear higher costs; however, these higher costs are almost always compensated by economies of scale.

In other words, a small company may have lower costs, but also a smaller sales force and less after-sales assistance.

HERE ARE THE ISSUES ON WHICH YOU AND YOUR COMPETITORS CLASH:

- MACHINING CENTER COST

- PERSONNEL COST

- COST OF ELECTRICITY

- COST OF RAW MATERIAL

- COMPANY OVERHEAD COSTS

HOW DOES YOUR PRODUCTION DEPARTMENT DIFFER FROM YOUR COMPETITOR’S PRODUCTION DEPARTMENT WHEN YOU ANALYSE THE ISSUES LISTED ABOVE?

I hope you did not answer “WITH QUALITY”, as the quality excuse is rather old. And you know something?

I am not saying that quality should be overlooked, just that it is an issue customers already take for granted today, and that your competitor is also talking about on its website, catalogues and so on.

THE TRUTH IS THAT, NOWADAYS, ONE ALWAYS SEES THE SAME THING IN ALL PRODUCTION DEPARTMENTS:

LONG QUEUES AT THE MACHINING CENTERS EQUIPPED WITH ROBOTS

And, as we have seen before, if you are the umpteenth company with rows and rows of machining centers trying to be competitive in the production department by doing the same thing your competitor is doing as far as the aforementioned issues are concerned, what are your chances of winning the challenge?

What I am suggesting is to move the battle to another battlefield, challenging, or better yet, eliminating the following issues thanks to the DIFFERENTIATION from the production/organization point of view:

- REDUCING STOCK ON HAND

- PRODUCING ONLY WHAT YOU SELL

- ELIMINATING EARLY PRODUCTION TO MEET DELIVERY DATES

- REDUCING MATERIAL HANDLING ACTIVITIES

- ELIMINATING IDLE TIMES DUE TO THE BALANCING BETWEEN OPERATIONS

- DRASTICALLY REDUCING PERSONNEL

- ELIMINATING UNNECESSARY PROCESSES

- NO MORE RE-WORK

That being said, I don’t think anyone is against it.

What I am certain of is that this way of operating, if implemented in a typical manufacturing company, is likely to place a great deal of stress on the organisation and on inter-personal relationships, generating frustration and loss of motivation, because you may change how you do things, but if the available instruments are outdated and inadequate, the situation can only get worse.

When I say outdated instruments, I don’t mean old in terms of age but rather in terms of design. Specifically, speaking about MACHINING CENTERS, there are many modern ones on the market.

But I keep seeing the same things, year after year: a spindle with pallet change, perhaps faster, more powerful, but as far as concepts are concerned, we are still where we were 20 years ago.

What the machining center manufacturers are continuing to improve is their own product, which is good yes, but the real jump in quality can only be made by analysing what the end customer really needs.

Today, the final customer is not trying to improve, for example, quick movements from 110 metres/minute to 120 metres/minute of the new machine.

As Henry Ford understood “a few years ago”, customers did not need faster, sturdier horses, but instead someone totally different, something that would end up revolutionising how we get around.

TODAY, IN ORDER TO EFFECTIVELY COMPETE, A COMPANY NEEDS TO PRODUCE ONLY WHAT IT SELLS, CUTTING DOWN ON STOCK ON HAND AND SPEEDING UP DELIVERIES.

The phrase above basically sums up what the new machine tools have to deal with in order to be successful. This is INNOVATIVE THINKING. It is not increasing the characteristics of machines which basically cannot be used to overcome the challenge summed up above.

LET’S GET TO THE POINT. HOW DOES ONE ONLY PRODUCE WHAT IS SOLD, REDUCE THE STOCK ON HAND AND DELIVER QUICKLY?

WITH THE METHOD:

FLEXIBLE PRODUCTION

Produce What You Sell, No Stock, No Stress, More Cash!

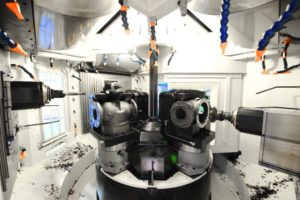

By analysing this new need, we identified a new market segment positioned between the TRANSFER MACHINE for very high volumes (special machine designed and developed to order) and the MACHINING CENTER, standard but with concepts that have been in use for 20 years.

THIS NEW MACHINE SUMS UP THE POSITIVE CHARACTERISTICS OF THE TWO WORLDS

The machine is based on a TRANSFER technology. In fact, the 4-station pallet rotates like a TRANSFER, so it is fast; however, instead of simple transfer units, 3 independent MACHINING CENTERS were used, with tool change and pallet rotation B axis.

This ensures flexibility, while at the same time everything is mass-produced, to cut down on costs and speed up deliveries.

THE MULTICENTER IS IDEAL FOR PRODUCING LOTS OF 500 PIECES AND UPWARDS

THE METHOD FLEXIBLE PRODUCTION

ALLOWS YOU TO CHANGE THE WAY YOU WORK COMPARED TO YOUR COMPETITORS!

Below is a summary of the strengths:

- VERY FLEXIBLE, IT ADAPTS ITSELF TO ALL MATERIALS AND PIECES TO BE PROCESSED.

- SUPER FAST TOOLING: PIECE CHANGE IN 15/20 MIN.

- FAST PRODUCTION: 3 SPINDLES ALWAYS IN OPERATION!

- LOWER TOOLING COSTS COMPARED TO COMMON MACHINING CENTERS.

- LOWEST INVESTMENT COST IN ITS CATEGORY, THANKS TO ITS MASS PRODUCTION AND DELIVERIES WITHIN 2-3 MONTHS FROM THE ORDER.

THIS METHOD WILL ROCK YOUR COMPETITORS,

ALLOWING YOU TO CHANGE THE GAME!

Moreover, you will gain a competitive advantage as you will be able to meet your customer’s needs in RECORD time, beating those competitors that continue to insist on traditional MACHINING CENTERS!

This is my explanation.

But, obviously, you could say that I am biased. If that is the case, keep reading below and you will come to one of the many CASES that normally take place whenever this method is used.

HERE IS A REAL CASE…

What I am illustrating today is a BEAUTIFUL and real case of a customer that manufactures components made of spheroidal cast iron.

Prior to installing a MULTICENTER, this company used common machining centers for their processing in the fleet, which nevertheless also included TRANSFER machines.

Here’s a quick summary of this case: I visited the customer’s facilities and analysed their work method, which was entirely respectable and consisted of a series of horizontal machining centers with pallet change.

Once we got back to the office, I asked the customer what was wrong with the method used for the production.

Basically, the customer found himself processing components not for the end customer, but for the finished pieces warehouse, based in the estimates of sales personnel who met every three months and decided what the market would need and in which quantities.

The customer, in a rather amusing way, told me that, after having had his sales staff take courses in reading the crystal ball and having understood that it simply does not work, not so much for the salespeople (as they were basically being asked to foretell the future) he now wanted to totally change his strategy.

His idea was not to force sales personnel to guess and gamble on the future, which rarely works out, resulting in high quantities of stock on hand which few were interested in buying.

What he basically wanted was a flexible system able to respond to the sales office so as to produce only the quantities that were ordered, quickly so as to satisfy the final customer, and automatically so as to reduce the stock on hand.

With these premises, the project was underway. Only a few months ago, we installed the MULTICENTER, which produces these pieces at a rate of 1 piece every 35 seconds, compared to the 3 minutes per piece on machining centers. Moreover, the machine can be re-tooled in a time ranging from 15 to 30 minutes, depending on the complexity of the pieces to be processed.

All this has allowed the end customer to:

PRODUCE ONLY WHAT HE SELLS, DELIVER FAST AND REDUCE THE STOCK ON HAND

The negative part for me was when, seeing the before and after results, I asked for an endorsement statement in favour of other companies which may be in the same situation and therefore could benefit from this different way of working.

It was negative in the sense that the customer refused to do so, the reason being that he did not want to reveal this new way of doing business to his competitors.

Today, we can boast the largest machinery fleet installed in this category, with over 100 centers sold both in Italy and abroad.

The advantage of mass-producing these standard machines means that:

THE MULTICENTER HAS THE LOWEST COST IN ITS CATEGORY!

Now it’s your turn! Answer the following 3 questions. It is very important to write your answers down instead of just thinking them, since writing requires concentration, that concentration that we often do not have for lack of time, and that however makes us make the WRONG decisions or, even worse, prevents us from deciding at all:

WHAT CHANGES IN YOUR COMPANY IF YOU ARE ABLE TO PRODUCE ONLY WHAT YOU SELL?

… AND WHAT HAPPENS IF YOU REDUCE YOUR STOCK?

IF YOU DO NOTHING AND CONTINUE DOING THINGS “THE OLD WAY”, WHAT HAPPENS?

Fill in the data below to download the video which compares the traditional way of production and this new approach.

Download immediately the video named:

“MULTICENTER VS MACHINING CENTERS”

Maurizio Porta

Expert in Flexible Production

Ita

Ita Deu

Deu