The world of Cnc metal working definitely concerns a very important part of companies, which are the root of a lot of industrial production markets.

We tend to talk about sectors like Oil&Gas, water fittings, different types of valves, Automotive and many others.

“CNC Metal Working” means the processing of raw parts from casting, printed, or from solid, which through the use of Computer Numerically Controlled Machine Tools (CNC) are made into “finished or semi-finished” products, ready to be sold or assembled with other components and then put on the market.

If you work in this industry, you know what I’m talking about.

Going into in any detail for those who dabble a bit these topics and terms, the most common techniques used for metal working are turning and milling.

Considering the milling technique, we are talking about CNC Machine Tools with rotating tools, while the piece remains still and has work done to it.

Therefore metal working takes place by “metal chip removal”, that is the excess material removed, to have a processed and finished product at the end of the cycle. Like a sculptor removes excess clay, this is the same as a CNC Machine Tool removing excess metal to reveal a finished part.

Much of the market concerns 250mm cube manufacturing.

We are therefore talking about small-size and medium-size parts, which are precisely in a 250mm processing cube.

But what happens if you have to do

Metal Working in a larger cube,

up to 500mm size?

We are talking about a bigger processing cube, which allows up to 4 times larger pieces than the 250mm cube.

So different scenarios come into play compared to the usual processing situation with smaller dimensions.

Can we find competitive solutions in the world of typical battery Machining Centers?

Not always…

Indeed, with the typical Machining Centers it is often so difficult to find competitive solutions and to get an excellent Cycle Time.

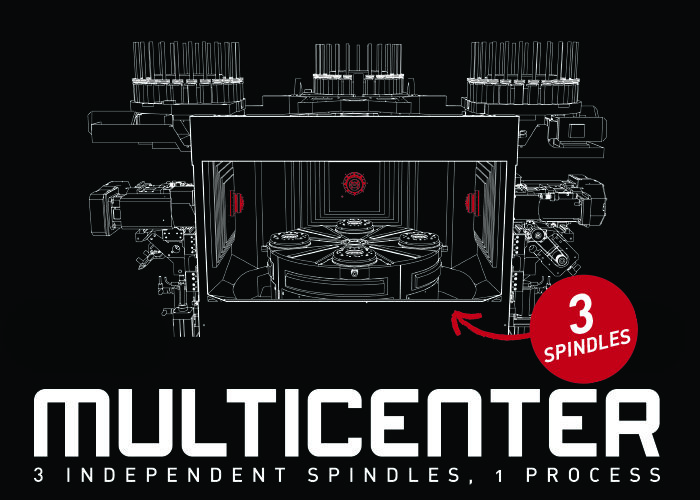

This is why

the MULTICENTER 3 Spindles PLUS is born

Click on the link below to see the technical specifications:

https://www.porta-solutions.com/en/multicenter-3-mandrini-iso-50.php

A CNC Machine Tool completely dedicated to the metal working in 500mm cubes.

Born after years of study and with proper equipment to be able to better face the hardest materials, such as Stainless Steel.

Here a typical production with 3 independent spindles on a 500mm machining cube:

Continue to follow me and I will explain you more in detail the features of this fantastic system of the Cnc world…

The problem of Metal Working

in a 500mm Cube

Moving on to this larger processing part, I want to make some remarks.

In fact, here we enter a narrow niche of metal working, which needs the right plants and the right rigidity to achieve excellent results in production.

Not all systems are suitable for this kind of metal working and even if it may seem the correct choice, it is always necessary to keep in mind the working parameters and other important considerations before choosing the definitive machinery.

If we talk about rigidity, a Machining Center is a very flexible CNC Machine Tool, which allows you to obtain excellent results on small production lots.

But at the same time, it has the problem of being HARDLY PRODUCTIVE by nature.

Having more machines with one spindle in order to try to increase productivity, brings deeper economical problems with the cost per piece.

MACHINING CENTERS ARE VERY FLEXIBLE,

BUT HARDLY PRODUCTIVE!!!

So, facing some productive situations with batteries of Machining Centers makes you non-competitive, so you can’t establish yourself on the market as a valid choice for your potential customers.

The other very important parameter is the CPK or CAPABILITY, that is the value that represents the process capacity of your production to be maintained over time.

Obviously, if you want to be reliable in the eyes of your customers, this data must be impeccable, to guarantee reliability and constant precision in the production of your pieces and be valued as a trusty supplier.

With Machining Centers you will have more processing phases on more Machine Tools, with more CPK values to keep under control.

Therefore, you will not have an absolute value, but an average of the CPK values of the different Machine Tools in progress.

For Metal Working it is important to have the CPK value as high as possible.

The solution to this dilemma are the MULTISPINDLE Machine Tools, which guarantee the highest possible CPK.

Why?

It’s easy! Because even if we talk about more processing phases on more spindles, the PRODUCTION PROCESS IS ONLY ONE.

We will therefore have a UNIQUE CPK VALUE, a more absolute value, which is not an average because it comes from a single production process.

So, in this regard, we will not have to deal with more processing phases, which represent more CPK values and an average among them to reach an unreliable final result.

In addition to the two above-mentioned problems, before buying a machinery we have to consider the skeletons in the closet, that is:

- the SPACE OCCUPIED by machinery;

- the ENERGY COSTS;

- the DIRECT PERSONNEL involved in production;

- the MAINTENANCE COSTS;

- the ROBOTS USED TO AUTOMATE.

You have to properly analyze all these items, one by one, drawing up a precise list of the costs you will have to bear in the mid and long term.

MULTICENTER 3 Spindles PLUS:

the definitive solution for metal working

with a 500mm cube!

Click on the link below to see the technical specifications:

https://www.porta-solutions.com/en/multicenter-3-mandrini-iso-50.php

After years of testing, tuning and continuous improvements, the Machine Tool made for metal working on a larger processing cube, up to 500mm, has finally arrived.

Why should a 3-spindle Machine Tool be the solution for manufacturing on a 500mm cube?

First of all, because we are talking about a STANDARD MACHINE, not an unreliable prototype like all the other special machines on the market.

In this case, being a Standard Machine Tool, the level of reliability of the plant is far above the other types of Machine Tools.

Compared to batteries of Machining Centers, we talk about a single machine, with a single production process to keep under control.

A single process, as mentioned above, leads to much higher CPK values and it is an absolute value.

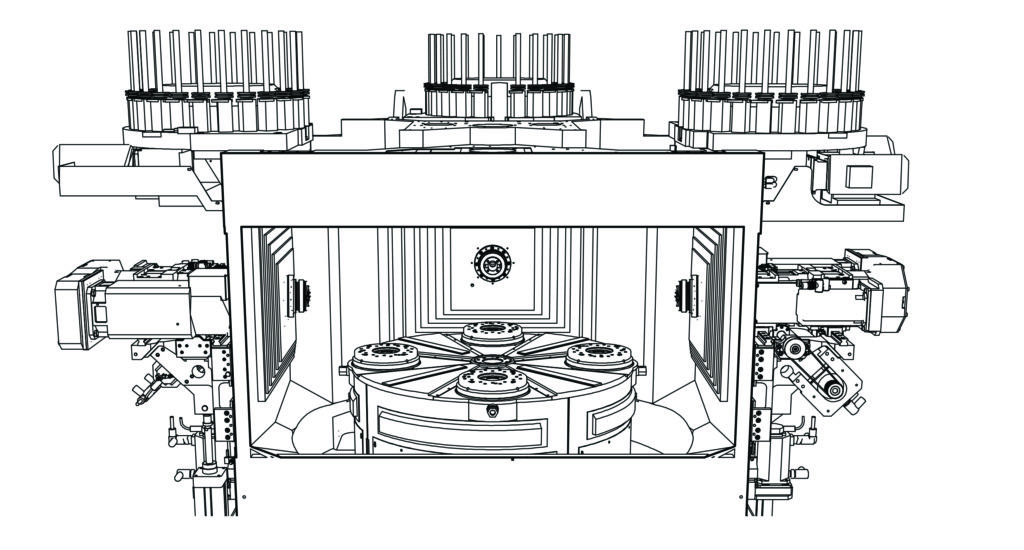

From a technical point of view, we are talking about a Computer Numerical Control Machine Tool with the turning work module option, and tool carousel with 72 or 120 pockets.

This machine replaces batteries of Machining Centers and lathes, making you more productive and competitive for the above-mentioned reasons.

Thanks to the model with 3 independent spindles, of course the Cycle Time is much lower than the model of the battery Machining Centers.

Here are the technical features:

- 4 stations and 3 modules;

- closed cell base for maximum stiffness;

- 3 strong XYZ modules, horizontal and made from die cast iron with a ISO50 or HSK100 tool coupling;

- tool magazine with 24 or 40 places per module for a total of 72 or 120 tools;

- 4 satellite tables in continuousmode(360.000 positions);

- 2 or 4 oil suppliers for each satellite table;

- standard ISO programming;

- Siemens® or Fanuc® CNC.

Technical representation of 3 independent spindles in a single production process:

But these are just some of the advantages you will have with the MULTICENTER PLUS.

These are the advantages of a unique production process:

- SPACE. You don’t have to have different machines for a single process, so you save a lot of space and you don’t need to enlarge warehouses. You can increase production by maintaining the same structure.

- ENERGY COSTS. Being a single Machine Tool we talk about only 1 robot vs. the 2-3 (and sometimes 4) robots that would be necessary for manufacturing on Machining Centers.

- DIRECT PERSONNEL. With a single process to keep under control, the operator will have only 33% of his time occupied, against a working time of up to 100% to keep different processes under control.

- EQUIPMENT COSTS. With only 4 clamps, compared to the 48 clamps in 3 Machining Centers, we have a much lower maintenance and equipment cost, which in the mid term helps you to really make the difference compared to all your competitors.

The MULTICENTER 3 Spindles PLUS represents a very important revolution for all those who have to face metal working on a 500mm processing cube.

This is because it is the Machine Tool that will definitely break the mold of “as it had always been done“, bringing this kind of work to a big step, the next one.

As Bill Gates said in his famous Microsoft presentation:

“Hello, I’m Bill Gates.

In this video you’re going to see the future.”

In the same way, I also enjoy copying this sentence and putting it in front of you, a little bit modified:

“Hello, I’m Maurizio Porta.

In this Machine Tool you’re going to see the future.”

But I want to confess something.

THE MACHINE ALONE WON’T DO A THING

Please, wait. Don’t think I’m crazy!

What I want to tell you is that the Machine Tool alone is a simple tool used to reach your production goals.

However, at the base of the use of this tool there must be a METHOD that helps you do a deeper and more concrete work.

The FLEXIBLE PRODUCTION METHOD helps you do that, studying the best way to implement the proper tools in your production department and planning the correct production strategy.

That’s why this METHOD is born. With it you can:

- Identify your production goals (cycle time, lots …)

- Plan the best strategy for your production model

- Choose the right tools for your goals (machines, tools …)

- Test your choices

- Control your results

Today this METHOD and this new Machine Tool technology (of which it is essential to understand all the makings) will lead you to increase your productivity, WITHOUT raising energy costs, the space occupied and your Machine Tools fleet.

Do you want to find out what it is and what to do in detail?

Discover it NOW and ask for a direct consultation

with one of our TECHNICAL TUTORS.

Click here https://flexibleproductionassistance.com/ to get more information.

If you want to go deeper on the topics of Flexible Production and Competitive Production

CLICK HERE

>>>https://www.flexibleproductionbook.com<<<

My book dedicated to users of Machine Tools

who want to make the leap in quality

is waiting for you!!!

To your results,

Maurizio Porta

MASTER TRAINER Method FLEXIBLE PRODUCTION

Ita

Ita Deu

Deu