When I talk about production with my clients, I never speak only of numbers in terms of the lots they produce, because in itself this is a fact that alone can mean very little.

Indeed:

- HOW MUCH YOU PRODUCE

It is a data point that is not directly connected with

- HOW MUCH YOU EARN

It is not necessarily true that if you produce more then you earn more. Otherwise the road, as you could guess, would be very simple to travel and it would be enough to simply take more orders.

These two elements of production data, unfortunately for many entrepreneurs, are not the same data and to produce more does not necessarily mean to earn more.

Many entrepreneurs and production managers often retreat from this fact.

Their solution to earn more is closely linked to “More production = More profit”, and therefore the road they choose to travel is to take more and more orders in order to increase production.

But obviously in the real world it does not work that way.

There are production strategies that allow you to increase your production, but they can very easily make you earn less profit than before.

On the contrary, there are other Production Strategies that can increase production and cause a greater profit.

The only real way you have to see how much you are earning is knowing how to read the balance sheets and financial numbers of your company. To bring out the data, indexes, and numbers that you need in order to see the picture of what your business model is and how it makes you profit.

But knowing how to read a budget includes different skills:

- Knowing which numbers to pull out;

- Comparing the financial ratios with your accountant;

- Knowing how to interpret these numbers and indexes correctly, alone, and adapting them to the context of your business model.

As you can see, it is not just a matter of doing two calculations on indexes, but also of developing the ability to interpret them.

And this is the most important skill that an entrepreneur and a Production Manager must learn to develop, especially in the production world, to understand if the production model and the strategies that are being used are going in the right direction.

In a simplified way, strategy and production models can also be beautiful to look at, but then if this beauty is not reflected also in the corporate financial data it remains a useless strategy.

The ultimate goal of adopting one Production Strategy over another is simply to earn more.

And I’d rather do it without the nice words spent by production consultants who give tips on how to improve Production Departments if these people do not know how to help you make more money.

“Do this, this, and this.”

Yes, but what then? Can you also tell me on a financial level what return in terms of earnings I will have compared to where I am now?

In many cases, unfortunately, they cannot give you an answer.

The concept is simple.

It is not that you decide tomorrow to implement a new plant and machinery of various kinds just because you like them and “it seems to you” that doing these things will lead you to improvement.

Deciding which Machine Tool to buy based on the earnings projections that this machine will be able to give to the company.

So simply say:

Production Strategy = Earn More

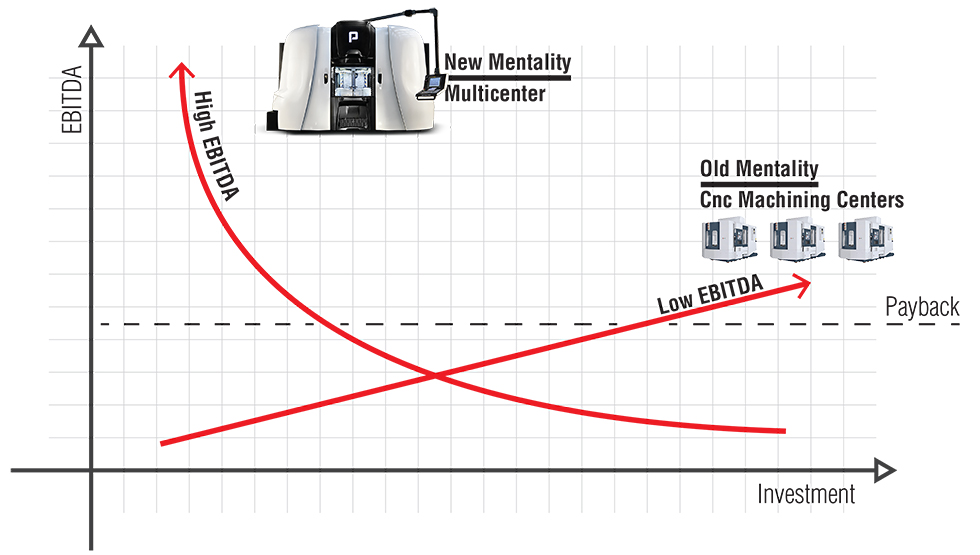

Below is a classic example of how I mean an investment that brings you more gains over the short and long term than another:

You can see from this image that, in many cases, with 3 Machining Centers, over a term of about 5 years, you earn much less than buying a single Flexible Machine with 3 spindles.

In this case, for example, we are talking about a MULTICENTER 3 spindles against 3 conventional Machining Centers.

Click here =====> www.porta-solutions.com/en/multicenter-machines

Obviously in the medium term, I’m not saying that you need to or will earn more tomorrow.

But the internal rule of a production company should be precisely the following:

“We buy new plants and machinery ONLY if these will help us earn more, otherwise we will not buy”.

Of course, we are not talking about “saving more”, because maybe you think that in order to earn more you have to spend less on buying machine tools.

No.

I’m saying that you have to have someone in the company who is in charge of making the correct calculations and understand which Production Strategy can be most profitable in the medium and long term.

Maybe a machine tool costs you more at the beginning than another, but if you can then do the correct calculations and you know how to correctly calculate the final TCO (Total Cost of Ownership), the maintenance costs of the plants and equipment in the total life of the machine, you will often be able to realize that the reality is quite different.

A machine tool that costs you little in the beginning, in many cases it will cost you a fortune in the medium term.

At the same time, a machine tool that at first has a higher cost, you will often be able to see that in the medium term it will have cost a lot less than many other alternatives.

It’s a question of numbers, not fantasies.

A fundamental number for production companies

Among the various budget and financial indexes that you can begin to analyze, the first and most on the surface is the ROI, Return On Investment. That is the data that makes you understand right away which investment return you are getting from the money you are putting into the company.

Simply put, what is making you money.

Then of course this is just the most superficial, fastest, and easiest way to calculate data, while if you want to go into more detail about the yield of your production you have to analyze all the other financial statement indices, such as the EBITDA (earnings before interest, taxes, depreciation, and amortization) and the ROE (Return on Equity).

But in this article I am deliberately concentrating only on ROI, because I would like you to focus only on the most available data at the moment to carry out your first profitability analysis of your production.

Correct Automation-Productivity and Machine Tool Report

So, as I said, if you want to quickly verify what is making your production profit you can immediately take your company balance sheets and go to calculate the ROI.

From this data you can immediately get an overview of the return on investment that is generating your money invested in that particular production.

At that point you will probably realize that, as happens most of the time, an increase in your production is matched by a decrease in earnings.

This is the classic case I see in our industry.

But if you are thinking of being the only one to make this kind of analytical mistake, don’t worry, because in reality it is one of the most common mistakes that most entrepreneurs make.

Usually the most sensible thing that you need to do to earn more in production is precisely that of…

- Try to get more jobs

- Increase Production

- Buy more equipment to meet the production.

In fact, if you increase your production like this, without a well-defined and studied planning and without a proven production method, the thing that you will be more natural to do will be to buy more machines, often Machining Centers, to be able to hold up the new request for product.

Except that this business model takes you straight to a collapse, even if you don’t know it at the moment, because increasing your fleet in this way is tantamount to a suicide premeditated by yourself, unknowingly.

But is this the only process to make your production earn more?

In reality this is the perfect way to make mistakes that could cost you dearly.

What is the only real way to earn more in profit with production?

Today there is a method, a technology and a new category of machine tools, which if you understand their potential, can lead you to increase your productivity, WITHOUT having to increase energy costs, space occupied and machinery.

Find out by requesting one on one advice from one of our TECHNICAL TUTORS.

Click www.flexibleproductionassistance.com for more information.

If you want to go deeper on the topic of “Flexible Production”,

CLICK HERE

>>> www.flexibleproductionbook.com <<<

My book, dedicated to users of machine tools that want to make the leap in quality & productivity, is waiting for you!!!

Maurizio Porta

MASTER TRAINER Method FLEXIBLE PRODUCTION

Ita

Ita Deu

Deu